Tuesday, November 15, 2011

Saturday, January 15, 2011

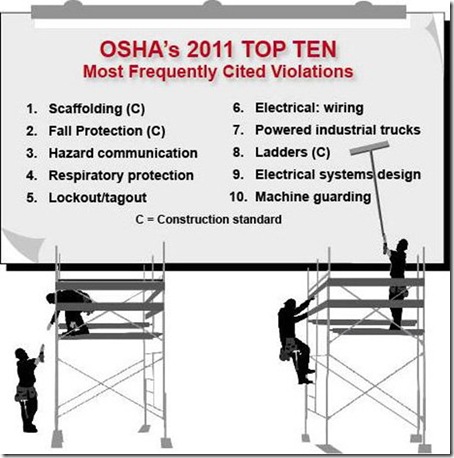

OSHA at 40: Time for a Makeover

Tom O’Connor | January 14, 2011

The notion that Democrats and Republicans could come together and enact legislation that would protect American workers from on-the-job injury or death seems almost unthinkable today, but almost exactly 40 years ago, that is precisely what happened.

On December 29, 1970, President Richard Nixon signed into law the Occupational Safety and Health (OSH) Act, a compromise that sought to “assure every working man and woman in the Nation safe and healthful working conditions and to preserve our human resources,” according to its text.

The OSH Act has saved many thousands of lives. If workers had the same risk of death on the job as they did in 1933, government figures estimated that

But today, the regulatory system that is the legacy of that landmark legislation is broken. The OSH Act has not been significantly updated since it became law and OSHA is hopelessly overmatched, struggling to oversee a 21st century workplace with 20th century tools. Nearly 5,000 American workers pay the price every year—with their lives.

OSHA is woefully understaffed, given the magnitude of its task. A mere 2,000 inspectors endeavor to cover more than 7 million worksites. The sanctions they can use against employers who routinely flout the law are too weak to function as deterrents.

When violations are discovered—all too often after the tragic fact—the penalties are laughable. The average penalty for a violation resulting in a worker’s death is only about $4,000.

Criminal penalties are nearly impossible to impose, even in cases of reckless disregard for workers’ lives. As a result, far too many employers make the calculation that it is simply cheaper to pay the fine, if they are one of the few who are caught, than it is to invest in a safe workplace.

Other federal agencies overseeing health, safety, and environmental regulations—from EPA to the FDA—all have been updated in the years since they were created to reflect changing circumstances. OSHA simply has not kept pace.

The fact is, OSHA will never have sufficient resources to protect all American workers. OSHA investigators cannot be everywhere at once.

ONE TO MANY

We need to rethink how to make workplaces safe. The answer lies not in developing new OSHA standards on a one-by-one basis. This process has produced important worker protections in the last 40 years, but business and industry interests have learned that they can block new regulations indefinitely by constant legal challenges and political pressure. As a result, new OSHA standards to protect workers have become exceedingly rare.

A whole new approach has been proposed by OSHA Director David Michaels. His new Injury and Illness Prevention Program Standard, if enacted, would require employers to assess their workplaces, determine what hazards are present, and come up with solutions.

The standard doesn’t tell employers exactly how they should prevent hazards, but instead provides flexibility in determining the best way to protect employees.

How would this avoid giving employers giant loopholes? Who’s to check? OSHA inspectors, already overstretched, would need a bigger enforcement budget, certainly.

But to stand any chance of success, these efforts must include meaningful worker participation. Workers know the hazards in their workplaces better than anyone. They must be allowed to participate actively in identifying workplace hazards and they must have the right to stop work, without fear of retaliation, if a hazardous situation develops.

Giving workers that measure of control over workplace safety in an environment of 7.2 percent private-sector union density would be no small feat. Health and safety advocates agree that safety committees should be mandatory in union workplaces. But in non-union shops, would a boss-dominated safety committee be desirable?

Workers, with or without a union, need new rights to protect themselves. Armed with that confidence, the workers on the Deepwater Horizon rig and at the Upper Big Branch Mine might have been able to prevent last year’s disasters at their workplaces.

Without it, we’ll be stuck in the same piecemeal system that fails to address the total picture of safety on the job—and wait for the next workplace disaster to strike.

Tom O’Connor is executive director of the National Council for Occupational Safety and Health, a coalition of unions, health and technical professionals, and others interested in promoting worker health and safety.

Thursday, October 21, 2010

USPS facing millions in fines for ‘willful’ safety violations

The United States Postal Service is set to lose tens of millions of dollars for a series of “willful” health and safety violations at its processing facilities across America.

While desperately searching for possible cutbacks to stem its multi-billion dollar losses, the organisation is being sued by the federal government for what are described as an “indifference to employee safety and health”. [Full Story]

Source: Post & Parcel

Sunday, July 18, 2010

OSHA Launches New Whistleblower Protection Site

The Occupational Safety and Health Administration (OSHA) says that workers who blow the whistle on safety violations and other unlawful practices “play an important role in assuring compliance with federal laws.”

The Occupational Safety and Health Administration (OSHA) says that workers who blow the whistle on safety violations and other unlawful practices “play an important role in assuring compliance with federal laws.” OSHA now has a new website specifically dedicated to its whistleblower protection program, http://www.whistleblowers.gov/. (Full Story)

Wednesday, June 30, 2010

OSHA Safety Citations Update OSHA Fines USPS for Safety Violations at Minneapolis MPC

[full story] | [USPS Also Cited for Violations at Southern Maine PDC]

Wednesday, May 5, 2010

OSHA Cites USPS for Safety Violations in Denver Findings Occur Just Days After Citations Issued in Providence

Five days after the Occupational Safety and Health Administration (OSHA) issued citations and fines of more than a half-million dollars to the Postal Service for safety hazards in Providence, RI, the agency charged the USPS in Denver with similar violations. The Postal Service willfully exposed workers to serious and potentially fatal hazards, including shock and electrocution, at the Denver BMC, OSHA said. The agency issued additional fines of $217,000.

The safety violations [PDF] in Denver mirror the hazards found at the Providence facility, and support APWU claims regarding the Postal Service’s failure to adhere to OSHA electrical safety standards.

In four “willful” violations, inspectors found postal employees working on equipment they were not familiar with and properly trained to maintain; on machinery with exposed, live parts that were not de-energized; in areas with potential electrical hazards; and without protective equipment for the eyes and face, exposing them to injury from electric arcs, flashes, or flying objects. These violations accounted for $210,000 in fines.

The remaining $7,000 fine was associated with a serious safety violation in which safety signs, symbols, or accident prevention tags were not used to warn employees about potential electrical hazards.

OSHA inspections of the facility were conducted between Nov. 2, 2009, and April 22, 2010, after the APWU Denver BMC Local filed a complaint. The local acted in response to a request from Industrial Relations Director Greg Bell, who urged local presidents to file complaints with OSHA regarding the Postal Service’s failure to comply with electrical safety regulations.

The APWU expects more safety violations to be issued by OSHA in the coming weeks. Check http://www.apwu.org/ for updated information.

Monday, April 19, 2010

Wednesday, April 7, 2010

Massey Mine Cited for 450+ Safety Violations Before Deadly Blast

The mine is owned by Massey and operated by its subsidiary, Performance Coal Co.

Early indications indicate the blast was caused by highly explosive methane gas leaking from sealed-off areas of the Upper Big Branch Mine in Raleigh County, W.Va.—the same cause of the 2006 Sago Mine disaster that killed 12 miners. New federal mine safety rules enacted after the Sago disaster included tougher new requirements for sealing off worked-out areas. [Full Story]

Source: AFL-CIO Now Blog

Wednesday, November 11, 2009

"Good Morning America" / Wal-Mart Linked to Swine Flu

If you missed Friday’s ABC "Good Morning America" report on Wal-Mart's punitive sick-leave policies -including demerits and docked wages, driving Wal-Mart employees to work no matter how sick they are-you can still see it at:

http://salsa.democracyinaction.org/dia/track.jsp?v=2&c=f90i7aSGjBl3GN0192fd1Y2n6y3uxuQP

An estimated 14,886,054 viewers saw the program.

Wal-Mart said it will not change its sick leave policies-which put both workers and customers at greater risk of catching swine flu because, well…. "because it is our policy." In a real humanitarian step, Wal-Mart has promised that no employee will be fired for having the H1N1 virus.

The story hit a nerve. A flood of Wal-Mart employees are sending their horror stories both to ABC and to the NLC. Other companies are also being exposed, including Home Depot and the major airlines.

We encourage you to weigh in about Wal-Mart's punitive sick leave policy on ABC/Good Morning America's site. If we can reform Wal-Mart, other companies will follow. The door is open. We must run through it. Let's keep the pressure up.

-ABC/Good Morning America, November 6, 2009 "Risking Demerits or Spreading H1N1?-

National Labor Committee, "Wal-Mart's Sick Leave Policy Risks Spreading Swine Flu; Retail Giant Flouts Recommendations of Centers for Disease Control"

Source: National Labor Committee

Monday, November 2, 2009

BP Hit with Largest-Ever OSHA Fine of $87 Million

Labor Secretary Hilda Solis announced today the Occupational Safety and Health Administration (OSHA) has levied the largest fine in its history—$87.4 million—against BP for failing to correct safety problems identified after a [1] 2005 explosion that killed 15 workers at its Texas City, Texas, refinery.

In a telephone press conference this morning, Solis said the fines are the result of BP’s failure to comply in hundreds of instances with a 2005 agreement to fix safety hazards at the refinery.

Solis said the fines represent the Obama Labor Department’s commitment to maintain [2] safe workplaces:

Let me be clear. This administration will not tolerate disregard of our laws. Employers have a legal and moral responsibility to protect their workers who ultimately are America’s most important assets. The laws are designed to level the playing field for all businesses and ensure that workers in any economic climate are kept out of harm’s way.

OSHA has issued 271 notifications to BP for failing to correct hazards at the Texas City refinery since the explosion. The agency also identified 439 “willful and egregious” violations of safety controls at the refinery.

Wayne Ranick, a spokesman for the United Steelworkers ([3] USW), which represents the BP workers, says the union has not yet read the citation, but “we have faith in OSHA.”

In the past we have offered to work with the company to address safety concerns and that offer still stands.

BP management initially tried to blame the workers for the explosion, but evidence collected in investigations by OSHA and the U.S. Chemical Safety Board forced the company to acknowledge it operated dangerous, obsolete equipment with a history of problems and malfunctioning control valves. Instead of venting flammable liquids to a flair, they were vented into the atmosphere, where they overflowed and exploded—even though OSHA had warned the company years before that the equipment was dangerous and should be replaced.

In addition to killing 15 people, the explosion injured 170 workers and obliterated 13 employee trailers and damaged 13 others, some as far as 300 yards away.

Jordan Barab, acting assistant secretary for OSHA, said the safety problems at BP are systemic.

There are some serious systemic safety problems within the corporation, specifically within this refinery as well. I think that just the fact that there still are so many life-threatening problems indicates they have a systemic safety problem at this refinery.

BP already has pleaded guilty to federal charges related to the explosion and agreed to [1] pay $50 million, the largest criminal fine ever assessed against a company for Clean Air Act violations. Six months after the explosion, BP [4] agreed to pay a $21.3 million OSHA fine, then the largest in the agency’s history.

Since the explosion, BP has settled more than 4,000 civil claims, paid from a $2.1 billion fund it set aside to resolve claims.

Solis ended the press conference by reiterating that job safety is a top Labor Department priority:

Our number one concern is the safety and protection of the current workers. We don’t need to see another loss of one life there. Our motto is that we would like to see people go into work and be able to come home to their families.

Article printed from AFL-CIO NOW BLOG: http://blog.aflcio.org

URL to article: http://blog.aflcio.org/2009/10/30/bp-hit-with-largest-ever-osha-fine-of-87-million/

URLs in this post:

[1] 2005 explosion: http://blog.aflcio.org/2007/10/25/bp-fined-50-million-in-texas-refinery-blast-that-killed-15

[2] safe workplaces: http://www.aflcio.org/issues/safety

[3] USW: http://www.usw.org/

[4] agreed to pay a $21.3 million: http://spewingforth.blogspot.com/2005/09/bp-fined-over-21-million-for-refinery.html

Monday, October 12, 2009

Article 14 – Influenza Cleaning Contingency

The additional cleaning requirements must be performed until the flu season (Fall of 2009 to April 2010) has ended, unless otherwise notified.

Recognizing that there are facilities that may not have career maintenance employees or those career maintenance employees may be incapacitated due to flue, the MMO provides for cleaning tasks to be performed by nonmaintenance employees. In this regard the language states:

If custodial resources are not available for these tasks in facilities in which the cleaning services are performed by career maintenance bargaining unit employees, including those facilities covered by relief from another office, the Senior Postal Official (SPO) may require non-custodial personnel to perform them. However, before non-custodial postal employees can perform these cleaning requirements, they must be trained on the proper use of the cleaning chemicals and provided with any necessary Personal Protective Equipment (PPE).

There is much that is still unknown on how the H1N1 influenza pandemic will develop. At this point the CDC does not expect the H1N1 's severity to increase this flu season and therefore the cleaning tasks and infection control strategies contained in this MMO should suffice. However, this can change. Should CDC's guidance change, additional information will be issued.

Gary Kloepfer

Assistant Director

Maintenance Division

American Postal Workers Union, AFL-CIO

Tuesday, July 21, 2009

Tablet Splitting: A Risky Practice

Tablet splitting often involves buying higher strength tablets and then breaking the tablets in half or quarter doses as a way to lower drug costs. For instance, a 30 mg tablet may cost the same amount as the 15 mg tablet. So a patient may try to save money by buying the 30 mg tablets and splitting them all in half. This might seem like a smart money-saving strategy, but the practice can be risky.

Why Splitting Tablets is Risky

You might get confused about the correct dose. There have been cases when people have purchased higher strength tablets intending to split them, but then they forgot to split them. Instead, they took the whole tablet. This led to accidentally taking too much medicine.

Equal distribution of medicine in split tablets is questionable. Studies have shown that the actual dose in each half of a split tablet often is different. So while the two halves may look the same, they don't necessarily contain equal amounts of medicine. Even if the tablet is scored with a line that runs down the middle, one half may actually have more medicine than the other.

Some tablets are hard to split. Some tablets are too small to split, may have an unusual shape that makes them hard to split, or may crumble more easily when split. Also, some people may not be able to split tablets correctly. These factors make it difficult to accurately split a tablet.

Not all pills are safe to split. Patients may mistakenly think that any pill can be split. But some pills, such as capsules and time-released drugs, should always be taken whole. For example, some tablets are coated with a substance that helps to release the medicine slowly. Splitting these tablets destroys the coating, which means you might absorb the medicine too fast or not at all.

What if You Still Want to Split a Tablet?

FDA has approved drugs where tablet splitting is part of the manufacturer’s drug application. "If the tablet is approved for splitting, the information will be provided in the drug’s professional prescribing information," says Mansoor Khan, Ph.D., director of the Division of Product Quality Research in FDA's Office of Pharmaceutical Science.

"FDA does not encourage the practice of tablet splitting unless it's specified in the drug’s professional prescribing information. If a patient is considering splitting a tablet, FDA recommends that the patient get advice directly from his or her doctor or pharmacist to determine whether it is appropriate or not for a particular drug."

This article appears on FDA’s Consumer Updates page, which features the latest on all FDA-regulated products.

Friday, July 10, 2009

Federal worker safety is focus of U.S. Department of Labor's OSHA nationwide inspection program

The Federal Agency Targeting Inspection Program (FEDTARG09) directive provides the procedures OSHA field staff must follow when conducting safety inspections at some of the most hazardous federal workplaces. The federal agencies targeted have experienced a large number of lost time injuries based on data from their fiscal 2008 Office of Workers' Compensation Programs reports.

"OSHA's mission of protecting worker safety doesn't begin and end with private industry," said acting Assistant Secretary of Labor for OSHA Jordan Barab. "It also extends to those who work in federal agencies. This directive is part of OSHA's continued efforts in assuring that the men and women who work to improve the lives of American citizens are provided safe working environments.

"This targeted inspection program was developed in 2008 in response to a Government Accountability Office audit report. Field inspectors conducted 109 inspections of high hazard federal worksites during 2008 and found multiple violations of OSHA safety and health standards. FEDTARG09 continues OSHA's commitment to inspect the occupational safety and health programs of federal organizations. For more information on the directive, visit http://www.osha.gov/OshDoc/Directive_pdf/FAP01_09-04.pdf.

OSHA's Office of Federal Agency Programs (FAP) serves as the point of contact for the federal sector regarding occupational safety and health issues. The FAP's purpose is to ensure that each federal agency is provided with guidance for implementing an effective occupational safety and health program. In addition, the FAP provides the president with progress reports on the safety and health programs of federal agencies.

Under the Occupational Safety and Health Act of 1970, OSHA's role is to promote safe and healthful working conditions for America's working men and women by setting and enforcing standards, and providing training, outreach and education. For more information, visit http://www.osha.gov.

OSHA News Release: 06/24/09

Tuesday, June 9, 2009

Practice Hospital Bed Safety

On this page:

- Beware of Entrapment

- Guidance

- Entrapment Zones

- Fire Prevention

- Home Use

- Safety Tips

- What is a Hospital Bed?

"Hospital beds are found in nearly all patient care settings or environments," says Joan Ferlo Todd, RN, a senior nurse-consultant at the Food and Drug Administration's (FDA) Center for Devices and Radiological Health (CDRH). "They are used not only in hospitals, but also in outpatient care centers, long-term care facilities, and in private homes."

CDRH reports that about 2.5 million hospital beds are in use in the United States. The center regulates these beds as medical devices.

"Many of today's hospital bed models are quite complex. Patients and health care professionals should understand how to use them properly, and manufacturers must provide adequate instructions for use," says Todd, who works in CDRH's Office of Surveillance and Biometrics.

Beware of Entrapment

"Patient entrapment is uncommon," says Todd, "but when it occurs, it's often fatal."

Between 1985 and 2009, FDA received reports of 803 incidents of patients caught, trapped, entangled, or strangled in hospital beds. The reports included 480 deaths, 138 nonfatal injuries, and 185 cases where staff intervened to prevent an injury. Most of the affected patients were frail, elderly, or confused.

"Not all patients are at risk for entrapment, and not all hospital beds pose an entrapment risk," says Todd. "But health care facilities, as well as patient caregivers, are urged to take a careful look at hospital beds. They need to determine if there are large openings that present an entrapment risk, and to take steps to minimize this risk."

Any type of rail or grab bar attached to a bed, as well as the fit of the bed mattress, should be assessed for entrapment risks, she adds. "It is important to view the hospital bed as a system," she says. "Not all mattresses or bed rails are suitable with any given bed frame."

Guidance

FDA regulates hospital beds through post-market activities such as analyzing reports of product problems and adverse events, says Todd. "Although the agency does not regulate the design of the beds, it offers safety guidance to industry."

FDA is a member of the Hospital Bed Safety Workgroup (HBSW), a partnership among the medical bed industry, national health care organizations, patient advocacy groups, and federal agencies.

In 2006, FDA with collaboration from HBSW issued "Hospital Bed System Dimensional and Assessment Guidance to Reduce Entrapment," recommendations for manufacturers of new hospital beds and for facilities with existing beds, including hospitals, nursing homes, and private homes.

"The guidance may also be used by health care facilities," says Jay A. Rachlin, director of CDRH's Division of Health Communication in the Office of Communication, Education, and Radiation Programs. "It offers useful information for health care facility staff."

Rachlin says the guidance, along with other educational products from FDA and the HBSW, have improved patient safety. "Manufacturers have redesigned their bed frames and their side rails to reduce the risk of entrapment."

Entrapment Zones

The guidance characterizes the head, neck, and chest as key body parts at risk of entrapment. It also identifies these seven potential "zones of entrapment" in hospital beds:

- within the rail

- under the rail, between the rail supports or next to a single rail support

- between the rail and the mattress

- between the rail, at the ends of the rail

- between split bed rails

- between the end of the rail and the side edge of the head or foot board

- between the head or foot board and the mattress end

Rachlin says that proper fitting rails can be useful. However, health care professionals and patients need to assess whether rails are necessary in each instance. "In addition to entrapment, there are other potential hazards associated with bed rail use, including serious injuries from falls when patients climb over rails, and having patients feel isolated or unnecessarily restricted," he says.

Fire Prevention

Fire is a rare safety risk associated with motorized hospital beds. "Fires are due mostly to a lack of maintenance," says Todd. "There are electrical shorts due to frayed or strained wires, motors overheat, or dust or other materials from the hospital fall into the motor casing."

She suggests these steps to cut the risk of fire incidents:

- Inspect the bed's power cord for damage.

- Don't connect the bed's power cord to an extension cord or to a multiple-outlet strip.

- Inspect the floor beneath the bed for buildup of dust and lint, which could clog the motor.

- Inspect the bed control panel covering for signs of damage where liquids could leak in.

- Check equipment for signs of overheating or physical damage.

- Keep linens and clothes away from power sources.

Home Use

Todd says there have been very few reports of safety incidents with hospital beds used in private residences. "This may represent underreporting by consumers," she says. "The reporting system for these incidents is set up for health care facilities, but consumers and home patients can still report medical device incidents to FDA through its MedWatch program."

She adds that hospital beds used at patients' homes are usually prescribed devices. "They're not required to be prescribed, but the beds are usually very expensive to rent or buy, and most patients get them for home through health plans."

It is important to ask that the bed meet the guidelines in the FDA guidance to reduce the risk of entrapment. Some hospital beds used at home may require patient or caregiver training, Todd says. "It depends on the complexity of the bed."

Safety Tips

CDRH offers the following safety tips for home use of hospital beds:

- Check the motors, especially for dust and debris.

- Ensure that each component—the bed frame, mattress, rails, and any added accessories—properly fits together. Make sure the mattress is the correct size for the bed frame so unsafe gaps are not present. If you see an opening let a health care professional know or call the manufacturer.

- When in doubt, consult the bed frame manufacturer to determine if a component or accessory is compatible with your bed frame.

- Use rails cautiously. Patients should not try to climb around or over the rails to get out of bed.

What is a Hospital Bed?

Todd says that there is no standard definition for hospital beds, a fact that consumers shopping for such a bed need to be aware of.

"A bed becomes a hospital bed when it meets the requirements for being a medical device," she says.

CDRH defines a medical device as "an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent, or other similar article that is intended for use in the diagnosis of disease or other conditions, or in the cure, mitigation, treatment or prevention of disease."

"There are beds sold in retail stores that don't meet the definition of medical devices under the law, but which may have some of the characteristics of a hospital bed," says Todd. "These beds may have features such as height-adjustment mechanisms or adjustable positions for the back and knee, or be fitted with snap-on rails. But they're not regulated by FDA."

She says that such beds fall under the jurisdiction of the U.S. Consumer Product Safety Commission. "If these beds are used with any type of rail, consumers should adhere to the same safety recommendations in place for hospital beds."

This article appears on FDA's Consumer Updates page, which features the latest on all FDA-regulated products.

Date Posted: June 9, 2009

For More Information

Friday, May 15, 2009

New Labeling Required for OTC Pain and Fever Medicines

Final Rule

In a final rule issued on April 28, 2009, the Food and Drug Administration (FDA) directed that labeling be revised for acetaminophen and nonsteroidal anti-inflammatory drugs (NSAIDs). These are two classes of commonly used drugs that are effective in reducing fevers and relieving minor aches and pain such as headaches and muscle aches. NSAIDs include aspirin, ibuprofen, naproxen, and ketoprofen.

The final rule applies to all OTC pain relievers and fever reducers, including those that contain one of these ingredients in combination with other ingredients, such as in cold medicines containing pain relievers or fever reducers.

Under the final rule, manufacturers must

- ensure that the labeling warns of the risk of stomach bleeding for NSAIDs and the risk of severe liver damage for acetaminophen

- ensure that the active ingredients of these drugs are prominently displayed on the drug labels on both packages and bottles

- revise the product labeling within one year of the date the rule was issued

Safety data reported in medical literature indicate that people sometimes take more acetaminophen than the labeling recommends. Others unknowingly take multiple products containing acetaminophen at the same time.

Exceeding the recommended dosage of acetaminophen may increase the risk of severe liver damage. Alcohol use can also increase the risk of liver damage with acetaminophen.

The risk of stomach bleeding may increase in people who use NSAIDs and who are taking blood-thinning drugs or steroids. Stomach bleeding risks also increase for people who take multiple NSAIDs at the same time, or in people who take them longer than directed. Alcohol use can increase the risk for stomach bleeding with NSAIDs use.

An FDA Advisory Committee meeting will be held on June 29 and 30, 2009, to discuss further steps the agency could take to reduce the risk of liver damage associated with acetaminophen overdoses.

This article appears on FDA's Consumer Updates page, which features the latest on all FDA-regulated products. Sign up for free e-mail subscriptions at www.fda.gov/consumer/consumerenews.html.

For More Information

FDA Press Release

www.fda.gov/bbs/topics/NEWS/2009/NEW02004.html

A Guide to Safe Use of Pain Medicine

www.fda.gov/consumer/updates/painmeds022309.html

Wednesday, May 13, 2009

OSHA, MSHA Move on Bush-Stalled Health and Safety Rules

The Occupational Safety and Health Administration (OSHA) is moving forward on several new workplace safety measures that languished for years under the Bush administration. The move follows last week’s unveiling of the Obama administration’s Labor Department budget that boosts OSHA’s funding by $51 million and includes the hiring of 160 new safety inspectors.

Source: AFL-CIO NOW BLOG

Thursday, May 7, 2009

President's FY 2010 Budget for FDA Invests Substantially in Food and Medical Product Safety

The U.S. Food and Drug Administration is requesting a budget of $3.2 billion to protect and promote the public health as part of the President’s fiscal year (FY) 2010 budget – a 19 percent increase over the current FDA fiscal year budget.

The FY 2010 request, which covers the period of Oct. 1, 2009, through Sept. 30, 2010, includes increases of $295.2 million in budget authority and $215.4 million in industry user fees. The FDA budget proposes two major initiatives for FY 2010: Protecting America’s Food Supply and Safer Medical Products. It also includes increases for current law user fees and for infrastructure to support critical agency operations. The FDA is also proposing four new user fees to facilitate review of generic drugs, register and inspect food manufacturing and processing facilities, reinspect facilities that fail to meet Good Manufacturing Practices and other safety requirements, and issue export certifications for food and feed.

“This historic increase in the FDA's budget is a great investment in public health,” said Joshua Sharfstein, M.D., acting commissioner of food and drugs.

The following are the FDA's key proposed budget increases:

Protecting America’s Food Supply ($259.3 million) – The goal of this effort is to protect American consumers by preventing intentional and unintentional contamination. This effort invests in priorities that strengthen the safety and security of the supply chain for foods. Supply chain safety and security relies on the principle of risk-based prevention with verification. Under this principle, the FDA holds all segments of industry accountable for ensuring that their products meet U.S. safety standards. The Protecting America’s Food Supply initiative focuses on foreign and domestic sources of ingredients, components, and finished products at all points in the supply chain, including their eventual use by the American public. Within this initiative, the FDA proposes to collect a total of $94.4 million in new user fees to register food facilities and increase food inspections, issue food and feed export certifications, and reinspect food facilities that fail to meet the FDA’s safety standards.

Safer Medical Products ($166.4 million) – This effort provides targeted resources to improve the safety of human and animal drugs, medical devices, vaccines, blood, and other medical products. It will allow the FDA to strengthen safety and security of the supply chain for medical products. The initiative also includes $46.6 million in new user fees for generic drug review and new fees to reinspect medical product facilities that fail to meet safety standards.

Current Law User Fees ($74.4 million) – In addition to the new user fees proposed for FY 2010, the FDA request also includes inflationary and other authorized increases for fees that support FDA review of applications for new human drugs (+$67.5 million), animal drugs (+$2.3 million), and medical devices (+$4.5 million).

Follow-on Biologics & Drug Importation ($5 million) – Within the Safer Medical Products initiative, the budget proposes a new authority for the FDA to approve follow-on biologics through a regulatory pathway that protects patient safety and promotes innovation, and includes $5 million for the FDA to develop policies to allow Americans to buy drugs approved in other countries.

Wednesday, May 6, 2009

USPS Notifies APWU of Flu Guidelines

The APWU has received notification from the Postal Service of “interim measures to be taken by management and employees” to address concerns about H1N1 influenza, commonly known as “swine flu.” The material provides guidance to managers for various scenarios, including when there are no known cases of the flu in the community or among employees, when there is a known case in the community, where there is a confirmed or probable case in a postal employee or in his or her immediate household, and in the event the federal government declares “a pandemic in progress.”

Postal Service Interim 2009 H1N1 (Swine Flu) Influenza Outbreak Guidance [PDF]

Installation Head Pandemic Flu Checklist [PDF]

Use of Surgical Masks During H1N1 Flue Outbreaks [PDF]

Maintenance Management Order on Pandemic Flu Cleaning Contingency [PD

Source: National APWU Website

Friday, April 24, 2009

Our day to remember the fallen: Workers' Memorial Day

Every April 28, the international labor movement stops to commemorate the lives and sacrifices of workers who never made it home, and to renew the struggle for safer and healthier workplaces. Here is a sampling of the events taking place next Tuesday around the world:

Every April 28, the international labor movement stops to commemorate the lives and sacrifices of workers who never made it home, and to renew the struggle for safer and healthier workplaces. Here is a sampling of the events taking place next Tuesday around the world:Canada(British Columbia): 10am, BC Federation of Labour hosts a rally in honor of BC's fallen workers at Hastings Park, Vancouver BC.

Unions in India will hold meetings all day April 28 with government ministry officials to push for a ban on asbestos.

The Irish Congress of Trade Unions will host a one-day conference on improving reporting of workplace fatalities and enforcement of Ireland's workplace safety laws.

The South African Department of Labour in partnership with the ILO will hold an event May 8 titled "Health and Life at Work: A Fundamental Human Right."

Here in the U.S., Secretary of Labor Hilda Solis will participate directly in Workers' Memorial Day, as she helps to break ground for a new national workers' memorial at the National Labor College in Silver Spring, MD.

Monday, April 6, 2009

FDA: Insulin Pens and Insulin Cartridges Must Not Be Shared

Insulin pens are pen-shaped injector devices that contain a disposable needle and either an insulin reservoir or an insulin cartridge. The devices typically contain enough insulin for a patient to self-administer several doses of insulin before the reservoir or cartridge is empty. All insulin pens are approved only for single-patient use (one device for only one patient).

The FDA is aware of incidents at two undisclosed hospitals involving more than 2,000 people in which the cartridge component of the insulin pens were used to administer insulin to multiple patients, although the disposable needles were reportedly changed among patients.

“Insulin pens are designed to be safe for one patient to use one pen multiple times with a new, fresh needle for each injection,” said Amy Egan, M.D., deputy director of safety at the FDA’s Division of Metabolism and Endocrinology Products in the Center for Drug Evaluation and Research. “Insulin pens are not designed, and are not safe, for one pen to be used by more than one patient, even if needles are changed between patients due to the risk of transmitting blood-borne pathogens.”

Patients exposed to shared insulin pens are being contacted by the two hospitals and are being offered testing for hepatitis and HIV. Some of the potentially exposed patients have reportedly tested positive for the hepatitis C virus, although it is not known if the virus was spread as a result of insulin pen sharing.

The FDA is working with the Centers for Disease Control and Prevention and professional organizations to address infection control issues related to insulin pens.

For Information:Information for Healthcare Professionals: Risk of Transmission of Blood-borne Pathogens from Shared Use of Insulin Penshttp://www.fda.gov/cder/drug/InfoSheets/HCP/insulin_pensHCP.htm

WorkersMemorialDay.jpg)